News

Screw and Barrel Refurbishment : The Comprehensive Guide

Screw and Barrel Refurbishment : The Comprehensive Guide

Screws and barrels are critical components in injection molding machines, extruders, and food processing equipment. Well-maintained screws improve machine efficiency, but long-term use or human error can cause wear and tear. This wear can reduce production capacity or even cause machine failure. Downtime results in ongoing labor and fixed costs, as well as lost production, potentially harming order fulfillment and market competitiveness. Besides purchasing new components, screw and barrel refurbishment offers a cost-effective solution to extend service life, reduce production costs, and improve product quality.

The Role of Screws and Barrels

Before discussing screw and barrel refurbishment, it's important to understand their functions in injection molding, extrusion, and food processing equipment:

Screws :

Melt and mix plastic materials.

Barrels :

Support the screw's operation and provide heat to facilitate melting. The interaction of screws and barrels transforms plastics into fully plasticized and evenly mixed melts, ensuring successful product molding.

Refurbishment or Replacement : Effective Evaluation

Choosing whether to refurbish a screw/barrel or replace it entirely is a complex decision. Seeking advice from experienced suppliers is a crucial first step for users facing this dilemma. A good supplier should possess both skilled refurbishment capabilities and professional knowledge to offer customized, cost-effective solutions that extend the service life of screws and barrels.

Evaluating a screw and barrel's suitability for refurbishment requires careful consideration. Not all components will benefit from refurbishment; excessive damage or wear may render it ineffective or even counterproductive. In such cases, suppliers should provide clear guidance to avoid wasting time on unnecessary inspections. Thorough evaluation, professional advice, and a comprehensive understanding of the specific conditions are essential to determine if refurbishment is the best option. The evaluation results directly influence a user's decision-making process.

Refurbishment or Purchase of New Barrels or Screws : Making a Choice

Users have varying perspectives on the maintenance and replacement of screws and barrels. With rising prices and thin profits, controlling costs is a major challenge for business owners. It's important to remember that replacing damaged parts isn't always the only solution. However, not all screw and barrel manufacturers are equipped for comprehensive refurbishment. Only professional manufacturers have the knowledge and experience to provide customized solutions that extend the service life of screws and barrels cost-effectively

Over time, screws and barrels naturally experience wear and tear, and are susceptible to accidental damage. Common problems include :

- Wear:

- Corrosion

- Fatigue:

- Negligence:

After the raw materials enter the screw and barrel, the continuous melting process causes wear, leading to reduced production capacity and quality.

Using strong chemicals or corrosive materials can lead to corrosion, negatively impacting the yield rate of finished products.

Continuous stress can cause metal fatigue, resulting in cracks, deformation, or even breakage of the screw and barrel.

If raw materials are not properly screened, they may contain foreign objects like screws. Additionally, starting the machine before it reaches the standard temperature can cause screw breakage and damage to the barrel bore.

The refurbishment and rebuilding of screws and barrels involves several key steps:

- Disassembly:

- Assessment :

- Restoration:

High-temperature annealing removes residual plastic, and hydraulic equipment is used to separate the screw from the barrel.

The wear condition of the screw and barrel is evaluated to determine the feasibility and cost-effectiveness of refurbishment.

Restoration methods vary depending on the degree of wear. Common screw treatments include weld overlay on the thread crest, surface hard chrome plating, straightening, and full-length polishing. Barrels may undergo bore grinding, bore grinding to true roundness followed by nitriding, or bore hard chrome plating to restore their size and performance.

Why Choose Nan Yun?

Nan Yun draws upon extensive experience and precision refurbishment equipment to provide professional evaluations tailored to each customer's unique screw and barrel conditions. We understand that every case is different and customize solutions to ensure they meet your specific needs.

Nan Yun Offers Cost-effective Solutions for Your Screws and Barrels

Common screw repair and rebuild processes:

- Carburization :

- Surface Accuracy/Flowability :

- Wear :

If the screw is carburized, polishing can resolve the issue.

Surface hard chrome plating improves product surface accuracy and plastic flowability when needed.

For screw wear, PTA welding is performed on the thread crest after a white steel base repair. This restores the screw to its original condition and can more than double its service life compared to a nitrided screw prior to refurbishment.

Common Barrel Repair and Rebuilding Processes

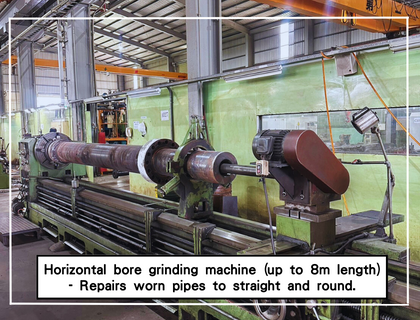

- Uneven Wear (Ovality) :

After long-term use, the barrel may experience uneven wear in different sections, resulting in ovality. This requires a horizontal boring machine to correct the inner diameter ovality, restoring true roundness and straightness. Finally, a vertical honing machine is used to grind the bore to the required size.

Nan Yun Offers Cost-effective Solutions for Your Screws and Barrels

Nan Yun possesses the precision equipment necessary for optimal screw and barrel repair and rebuilding, including :

- Hydraulic Machines and Equipment :

- Horizontal Bore Honing Machine :

- Vertical Bore Grinding Machine :

- PTA Thread Top Spray Welder :

Used to separate the screw from the barrel when it cannot be removed normally due to foreign objects or solidified plastic.

Corrects barrel bore ovality, restoring true roundness and straightness to prevent offsets during bore grinding.

Grinds the barrel bore to the required size (up to 8 meters capacity), ensuring inner diameter straightness, roundness, and surface roughness.

Employs PTA powder plasma welding to fully fuse the weld bead with the parent metal. The dual alloy composition (nickel, tungsten, cobalt, etc.) significantly extends screw service life.

Nan Yan : Your Trusted Partner for Screw and Barrel Solutions

Regular refurbishment of screws and barrels is crucial for extending their service life and ensuring product quality. Nan Yun Industrial has a professional service team with rich experience to provide comprehensive refurbishment services, including reverse engineering, design changes, and old product refurbishment. We are committed to providing customers with the best quality service and the most competitive prices, helping them stay ahead in the ever-changing global economy. Contact us today to discuss your refurbishment needs.

Learn more about screws and barrels : 3 Minutes to Understand Screw and Barrel for Injection Molding, Extruders and Food Processing.