Products

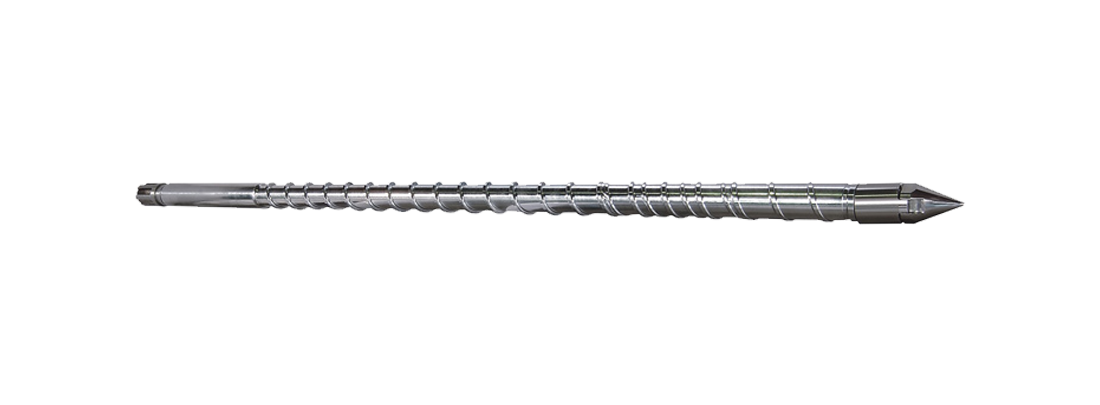

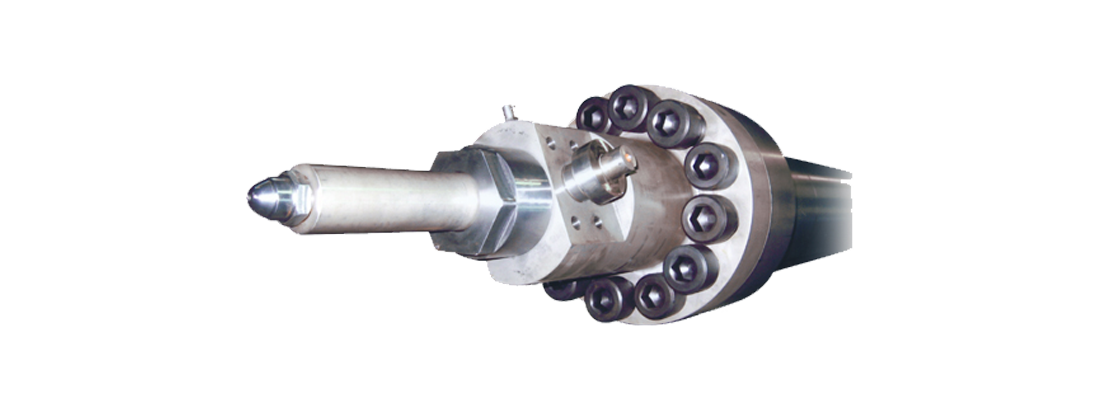

Single Screw and Barrel for Rubber Injection Molding

Single Screw and Barrel for Rubber Injection Molding

Importance of Screw and Barrel in Rubber Injection Molding

The screw and barrel play a crucial role in the rubber injection molding process, ensuring proper material flow, melt homogeneity, and controlled injection into the mold cavity.

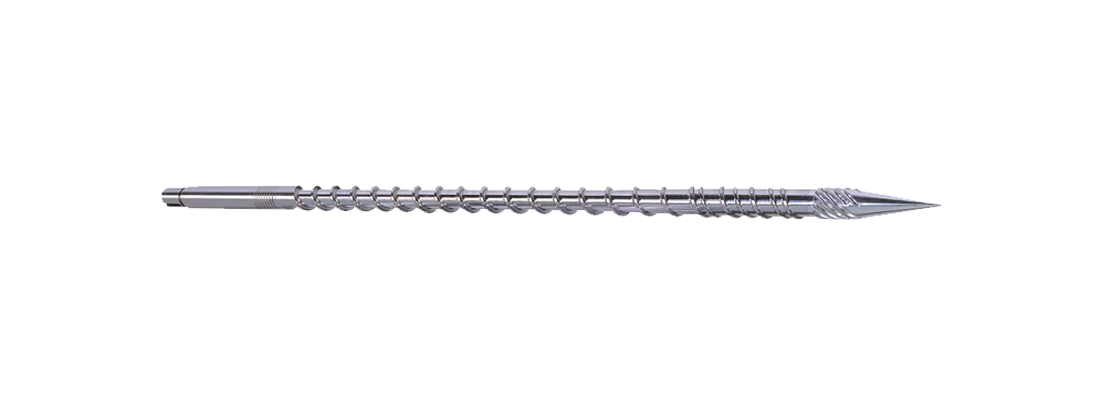

Screw Length in Rubber Injection Molding

The length of the screw (8000 mm) affects the plasticizing and melting process of the rubber material. A longer screw allows for a larger melting zone and better heat transfer, resulting in more efficient melting and mixing of the rubber compound. It provides a higher degree of control over the viscosity and homogeneity of the melt, leading to improved part quality and dimensional stability.

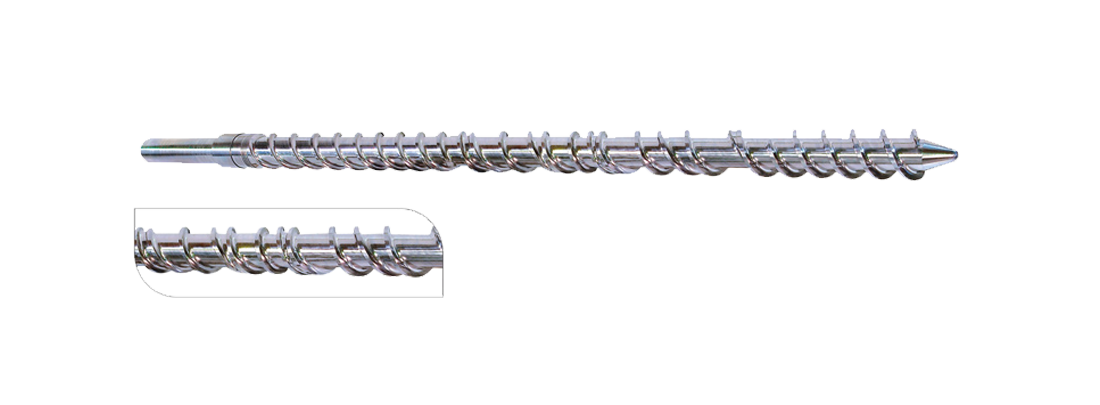

Diameter of the Screw in Rubber Injection Molding

The diameter of the screw (Ø16~Ø450 mm) also plays a vital role in rubber injection molding. It determines the amount of rubber material that can be processed in a single injection cycle. A larger screw diameter allows for a higher shot capacity, enabling the production of larger parts or higher quantities of smaller parts in each cycle. It also facilitates better material flow and reduces the risk of material degradation or overheating.

Benefits of Using Large Screw and Barrel

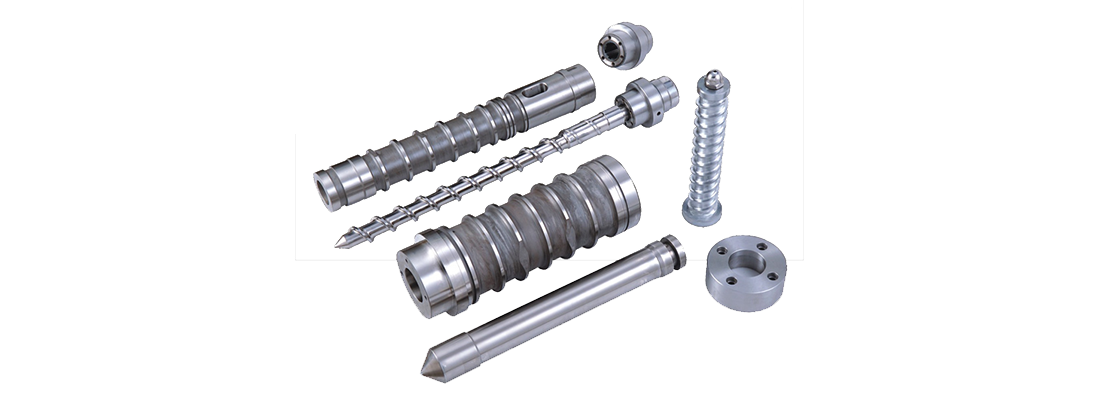

Using large screw and barrel components in rubber injection molding offers several advantages:

- Size and Capacity: Large screw and barrel systems are designed to handle higher volumes of materials and are typically used in industrial-scale production environments. These systems have a larger diameter and length, allowing for greater material throughput and faster processing speeds. They are capable of handling larger batches of raw materials, making them suitable for high-volume manufacturing.

- Application Range: The size of the screw and barrel also determines their application range. Large screw and barrel systems are commonly used in industries such as automotive, construction, and packaging, where high production volumes and larger product sizes are required. These systems excel in processing materials such as plastics, rubber, and metals for large-scale manufacturing applications.

- Output and Production Efficiency: The size of the screw and barrel directly influences the output and production efficiency of the machinery. Large screw and barrel systems can process larger quantities of materials in a shorter time frame, resulting in higher production output. They are capable of achieving faster cycle times and higher throughput rates, making them ideal for meeting the demands of large-scale production.

- Reduced Shear Heating and Material Degradation: Large single screws and barrels help reduce shear heating during the injection molding process. The extended length and larger diameter promote better cooling and minimize the risk of material degradation, ensuring high-quality rubber parts.

The use of a large single screw and barrel in rubber injection molding offers numerous benefits, including enhanced processing efficiency, improved mixing, and reduced material degradation. Proper design considerations, such as screw configuration, diameter, length, and barrel lining, are crucial for achieving optimal results. If you have any needs or questions about large screws and barrels for rubber injection molding, welcome to contact us!

| Length | Circularity | Straightness |

|---|---|---|

| 50~1,000 mm | 0.005 mm | 0.005 mm |

| 1,000~2,000 mm | 0.01 mm | 0.01 mm |

| 2,000~4,000 mm | 0.015 mm | 0.015 mm |

| 4,000~6,000 mm | 0.02 mm | 0.02 mm |

| 6,000~8,000 mm | 0.03 mm | 0.03 mm |